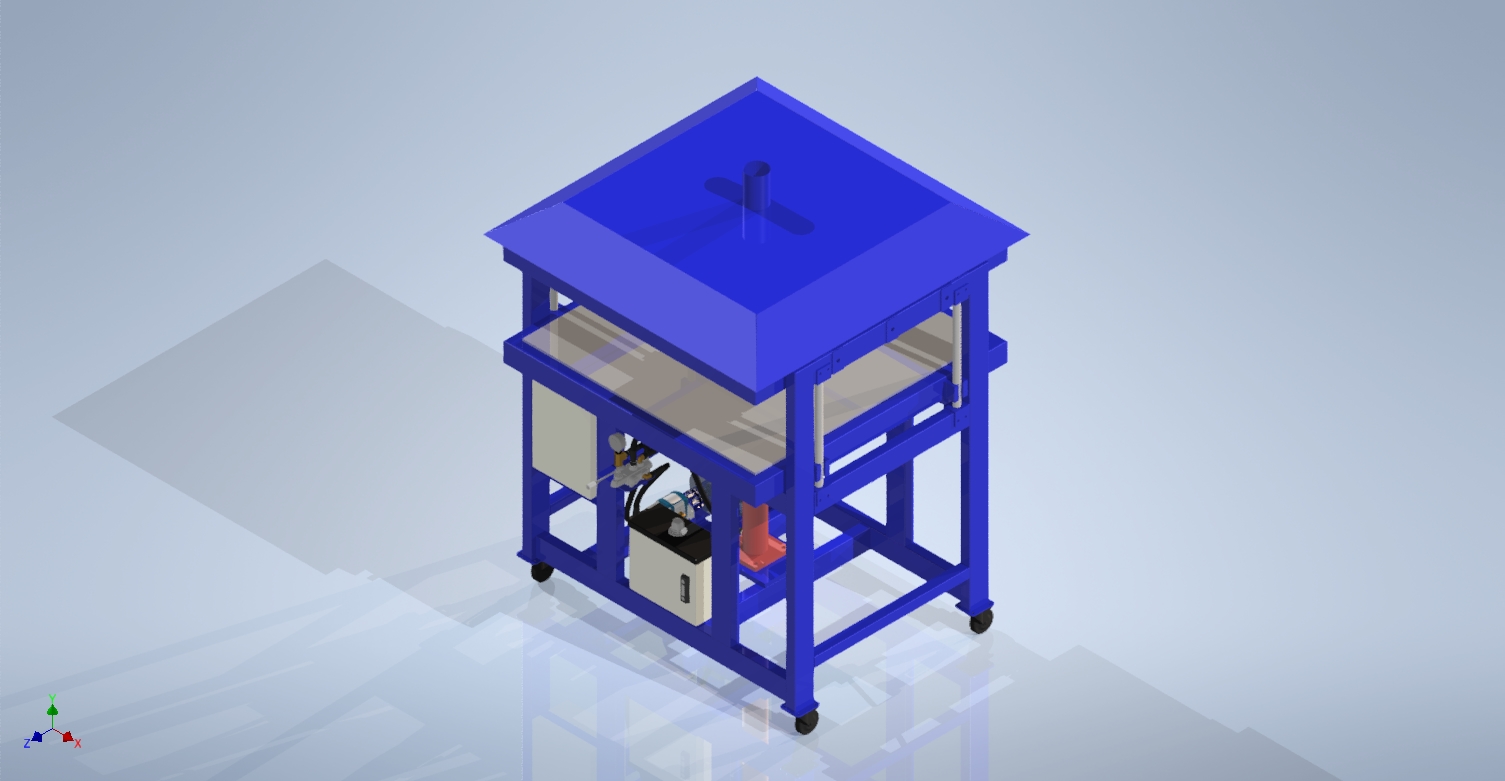

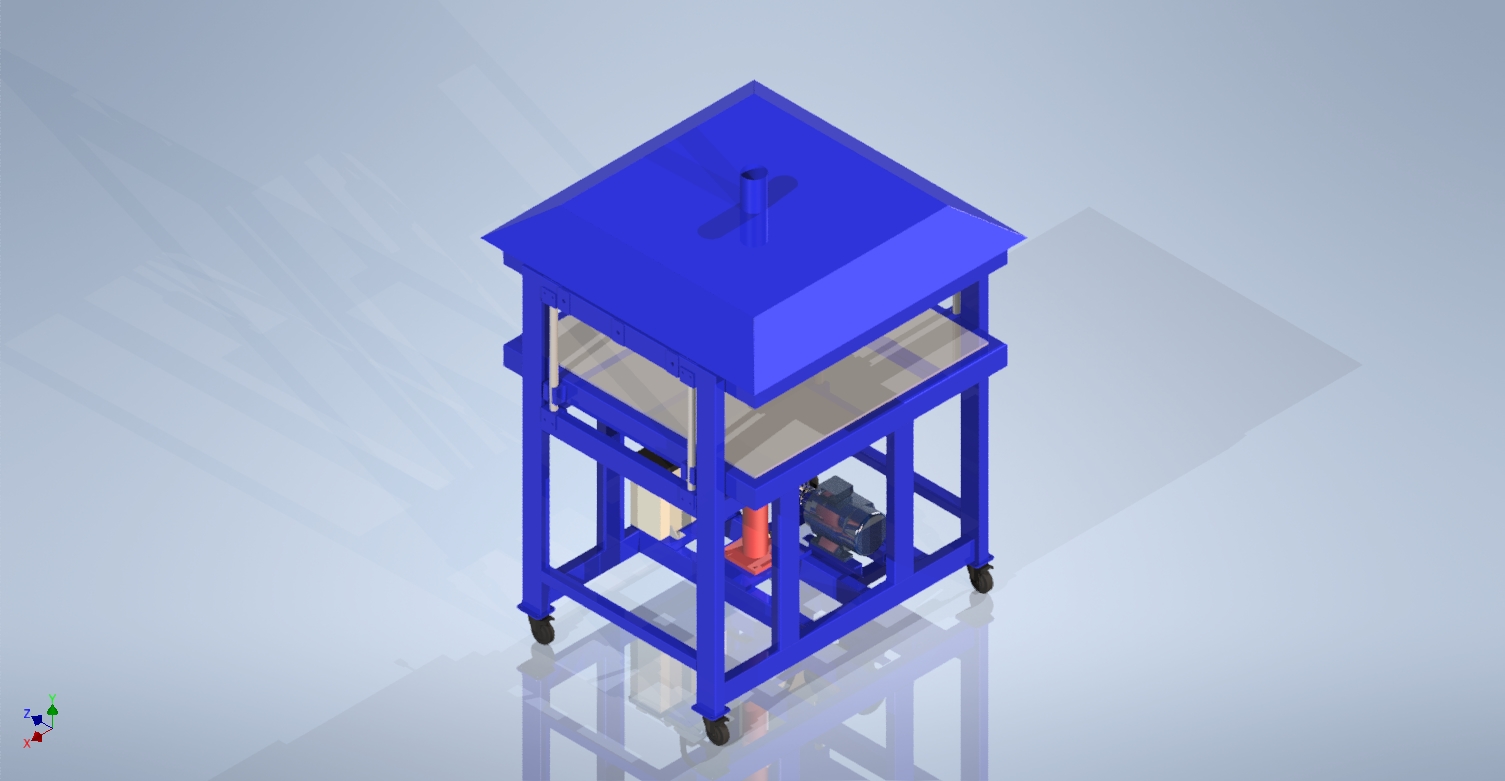

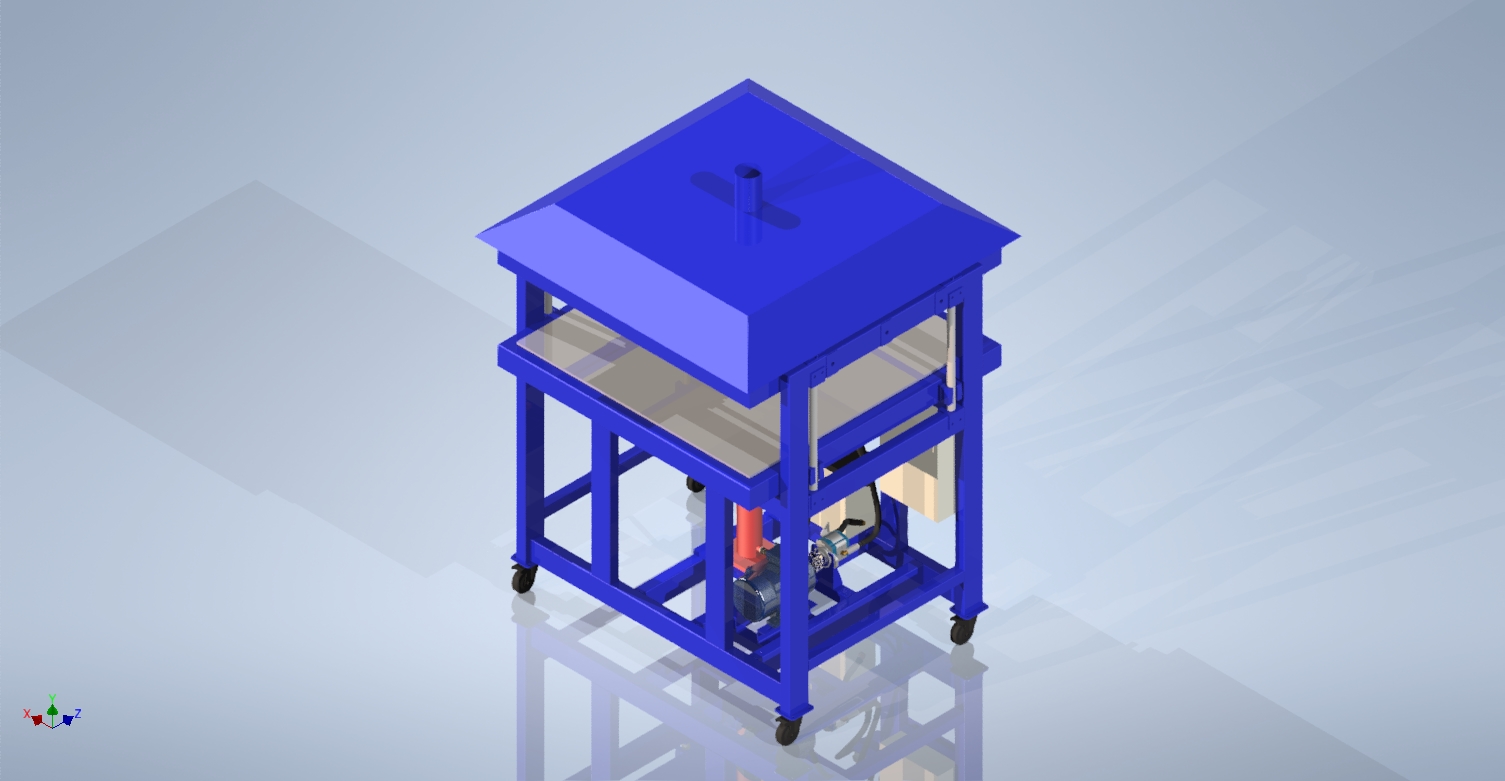

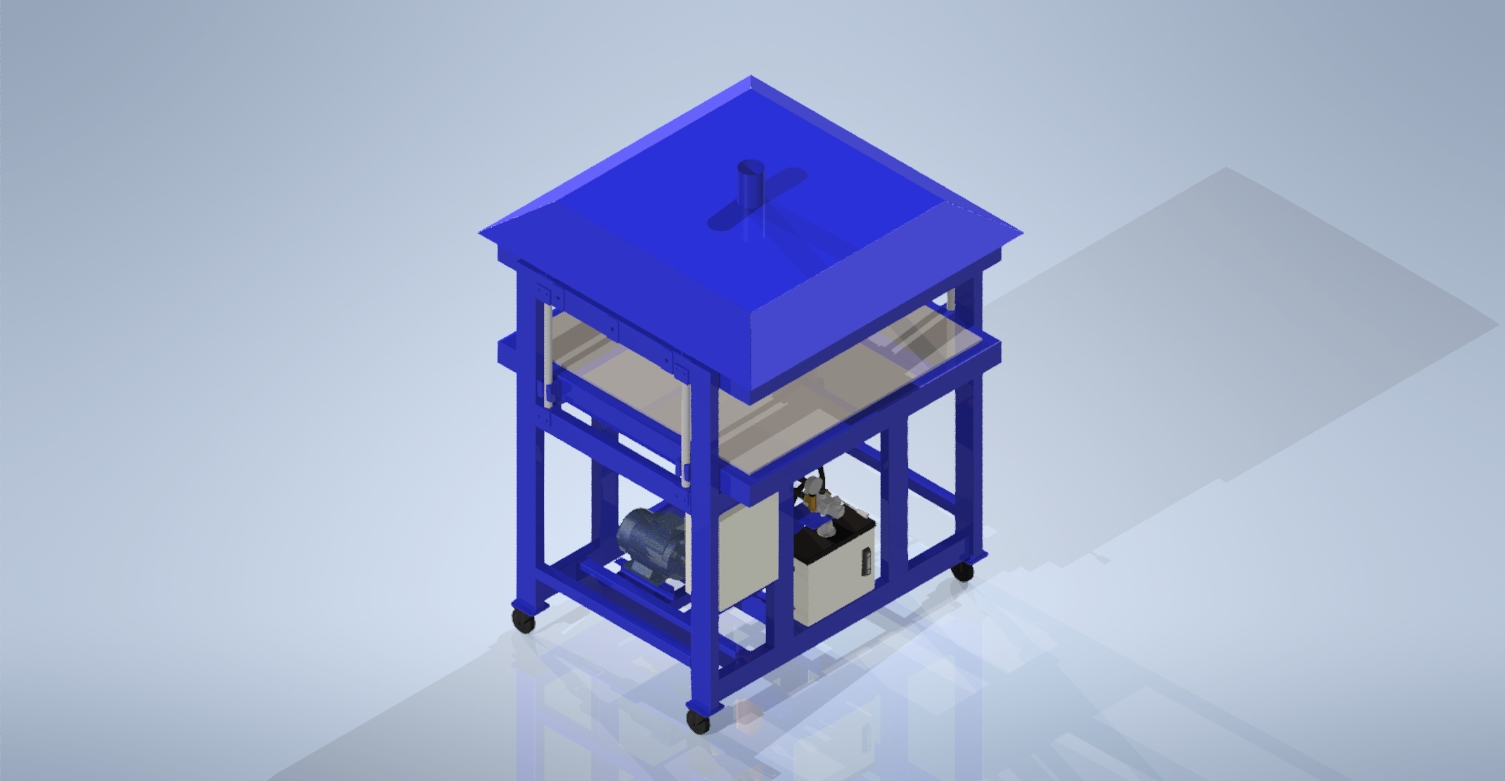

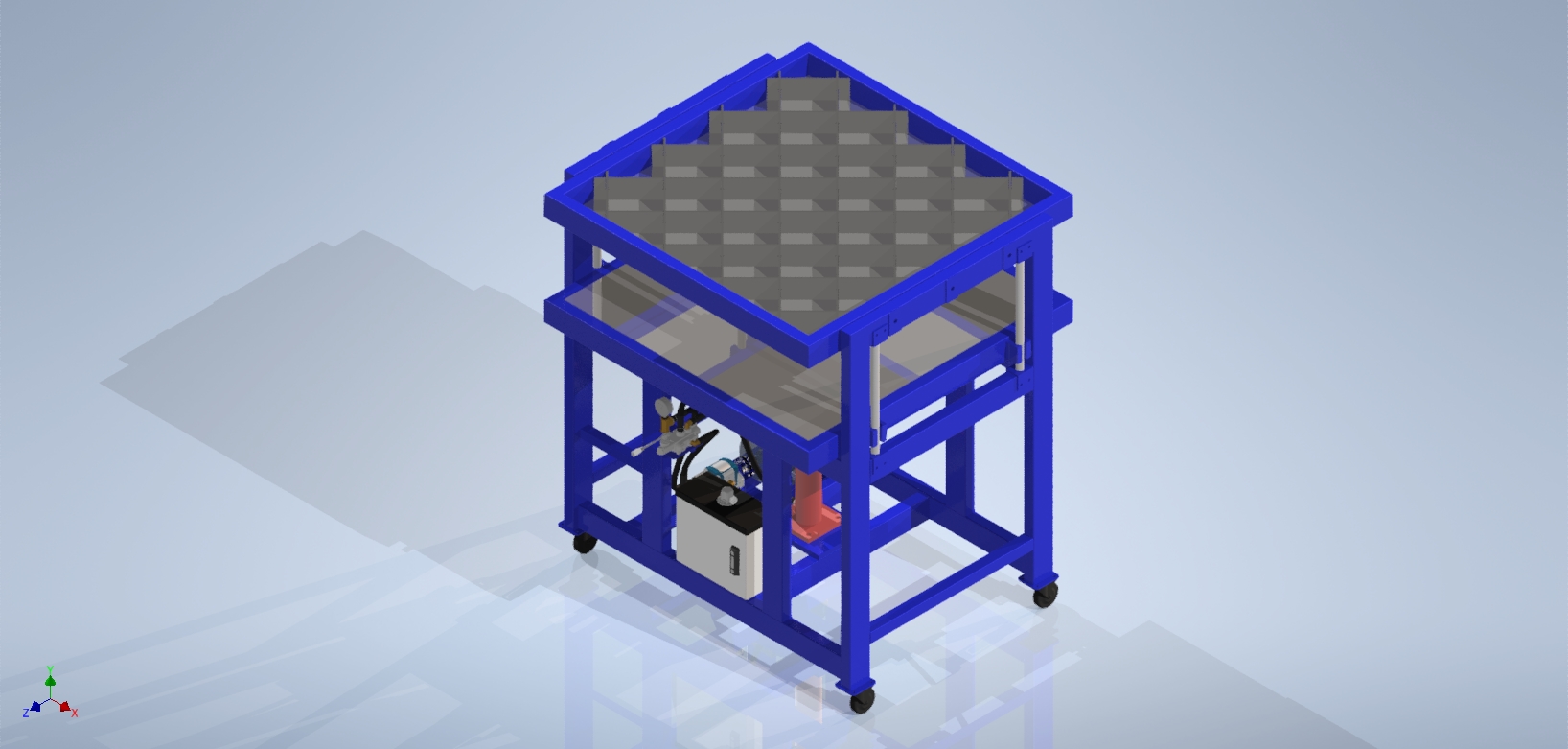

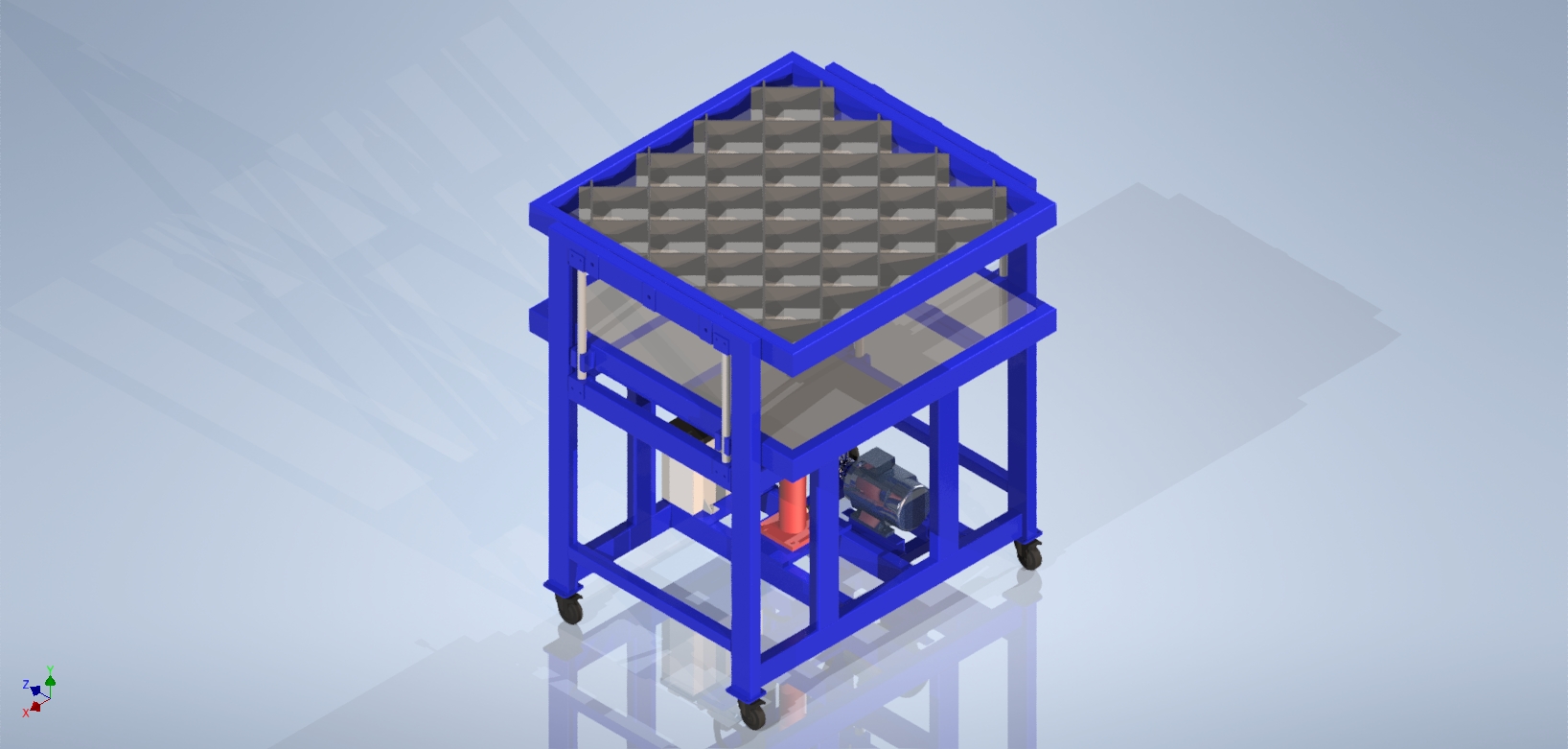

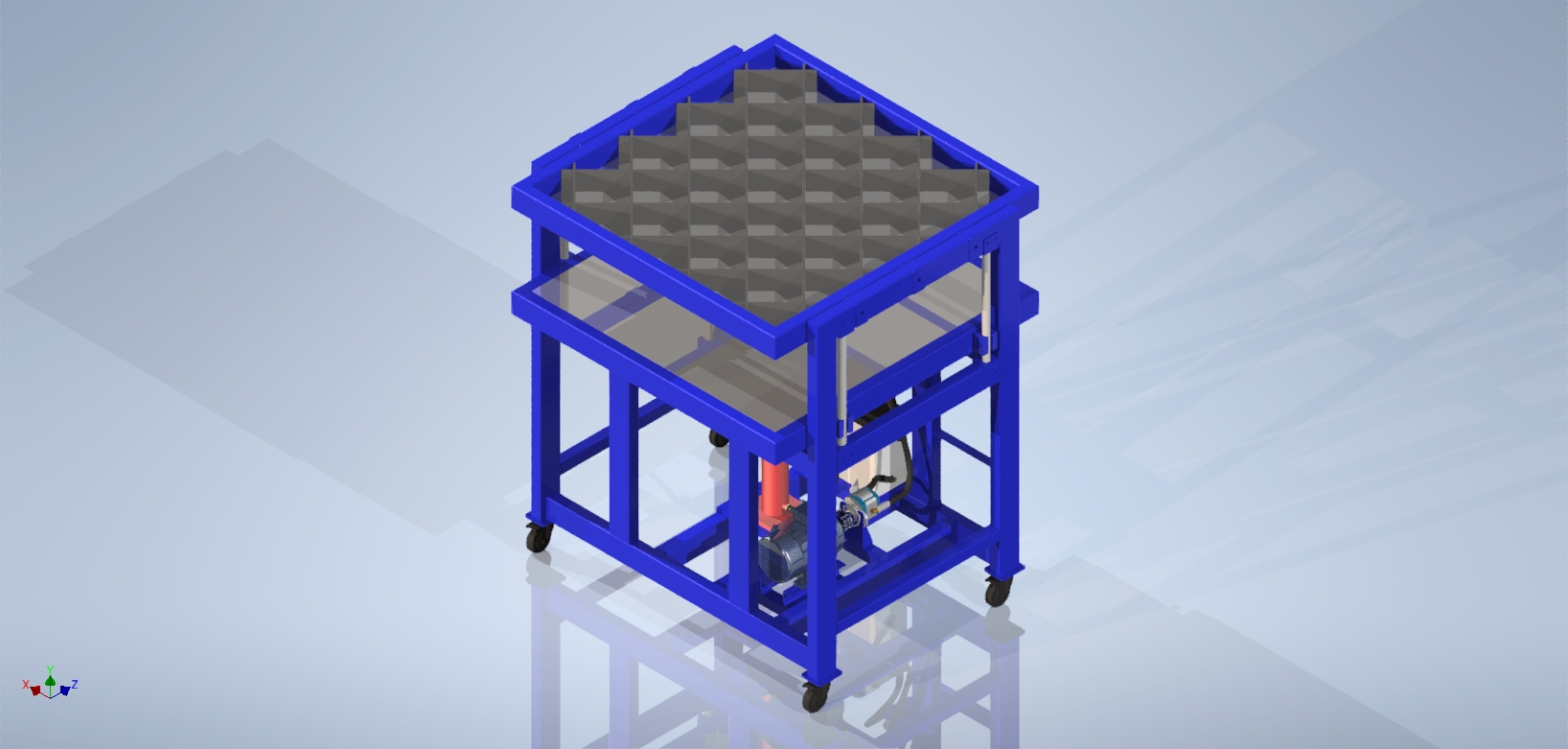

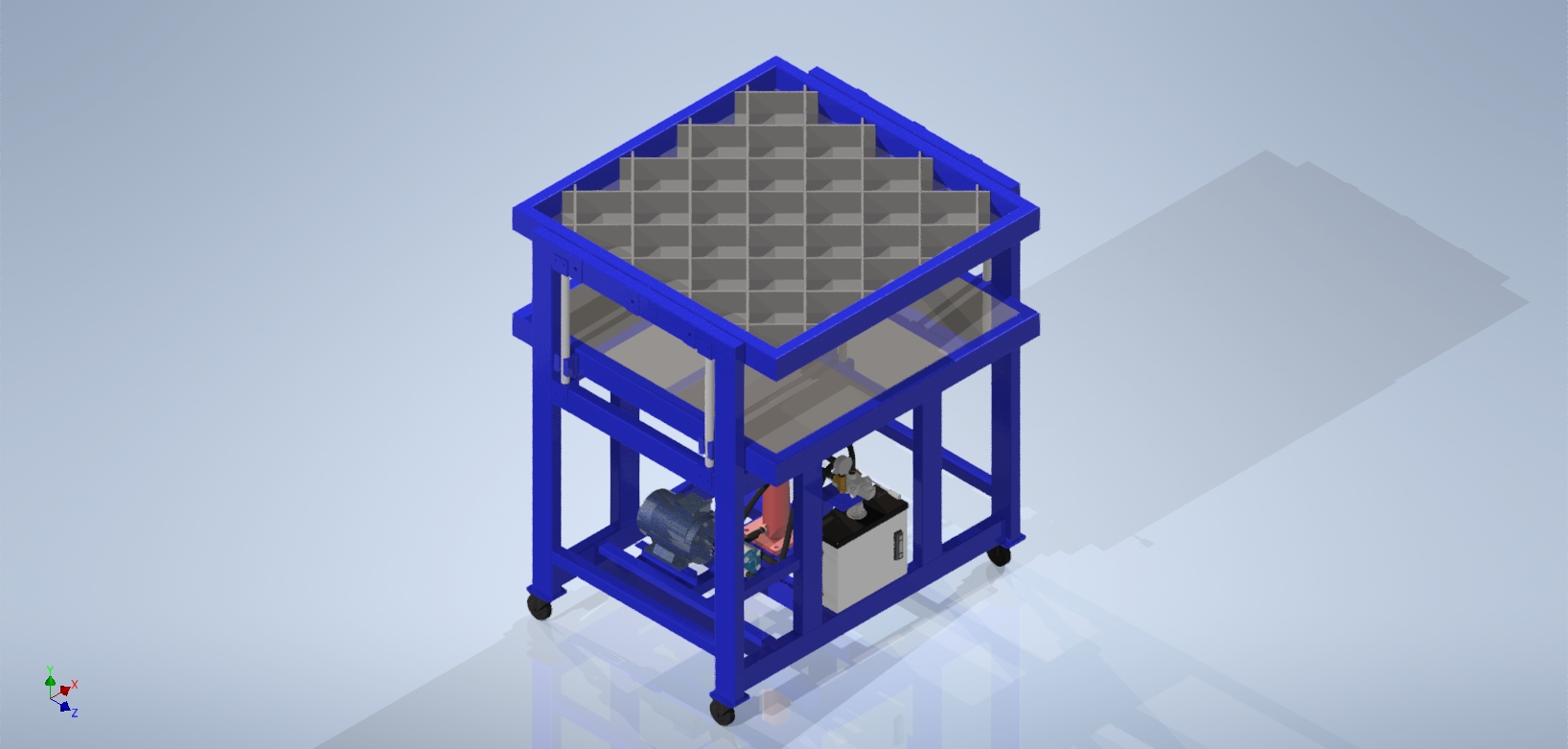

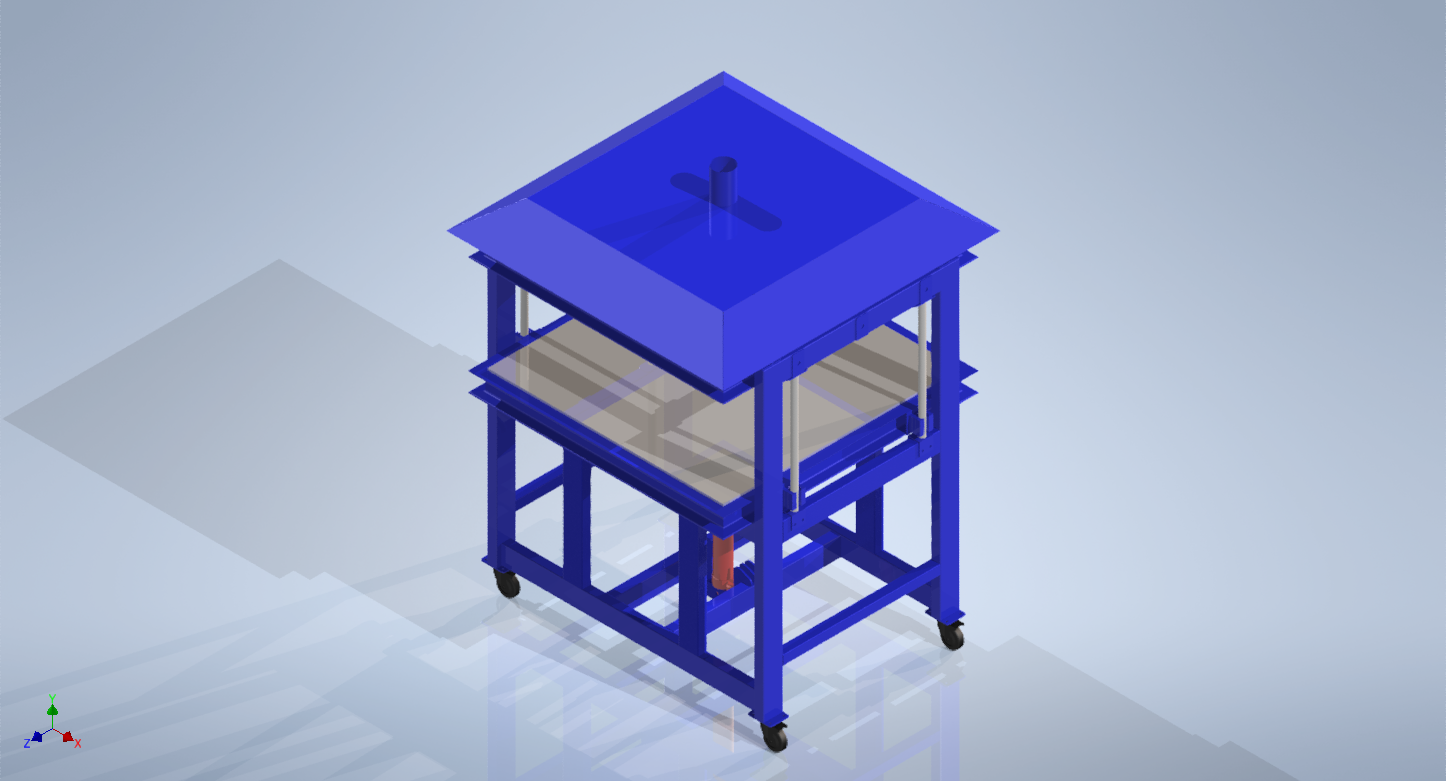

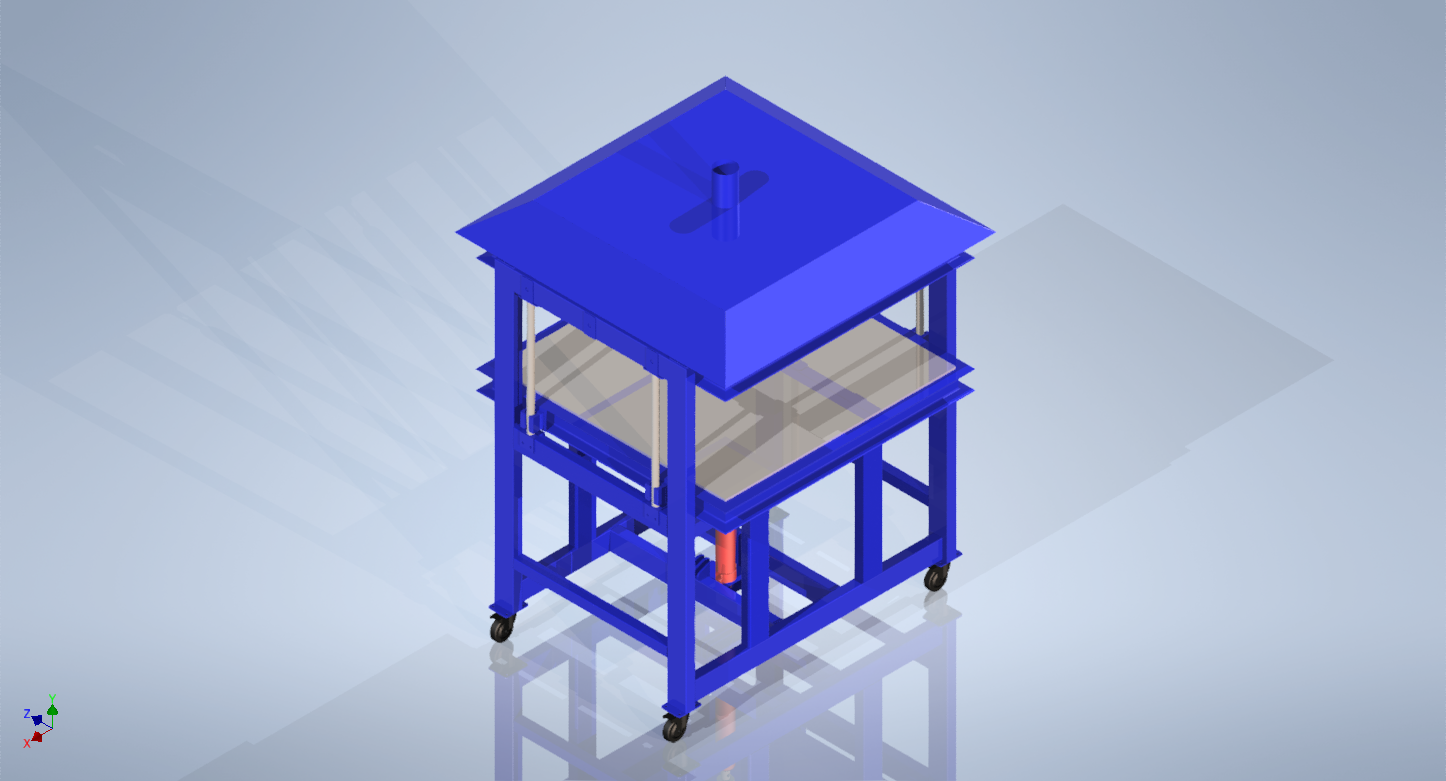

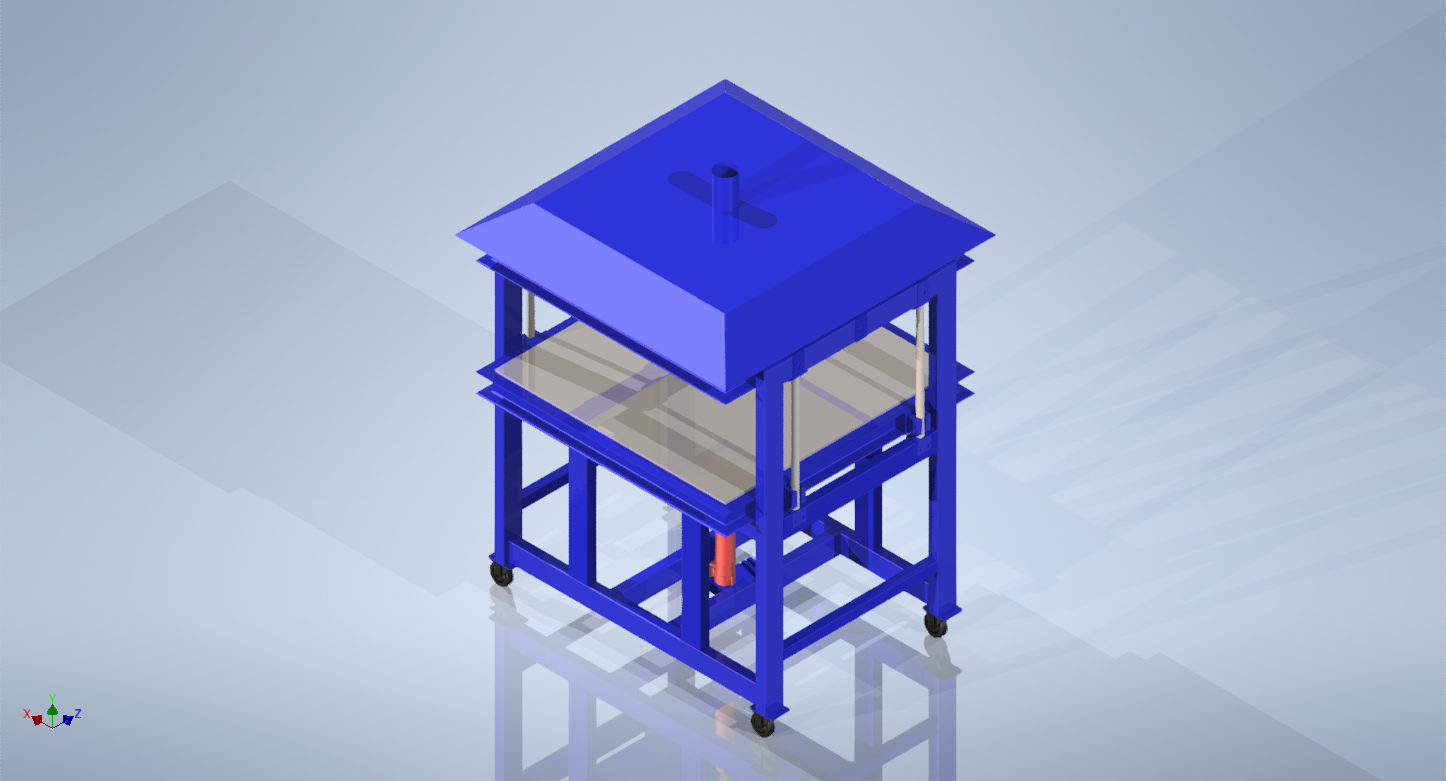

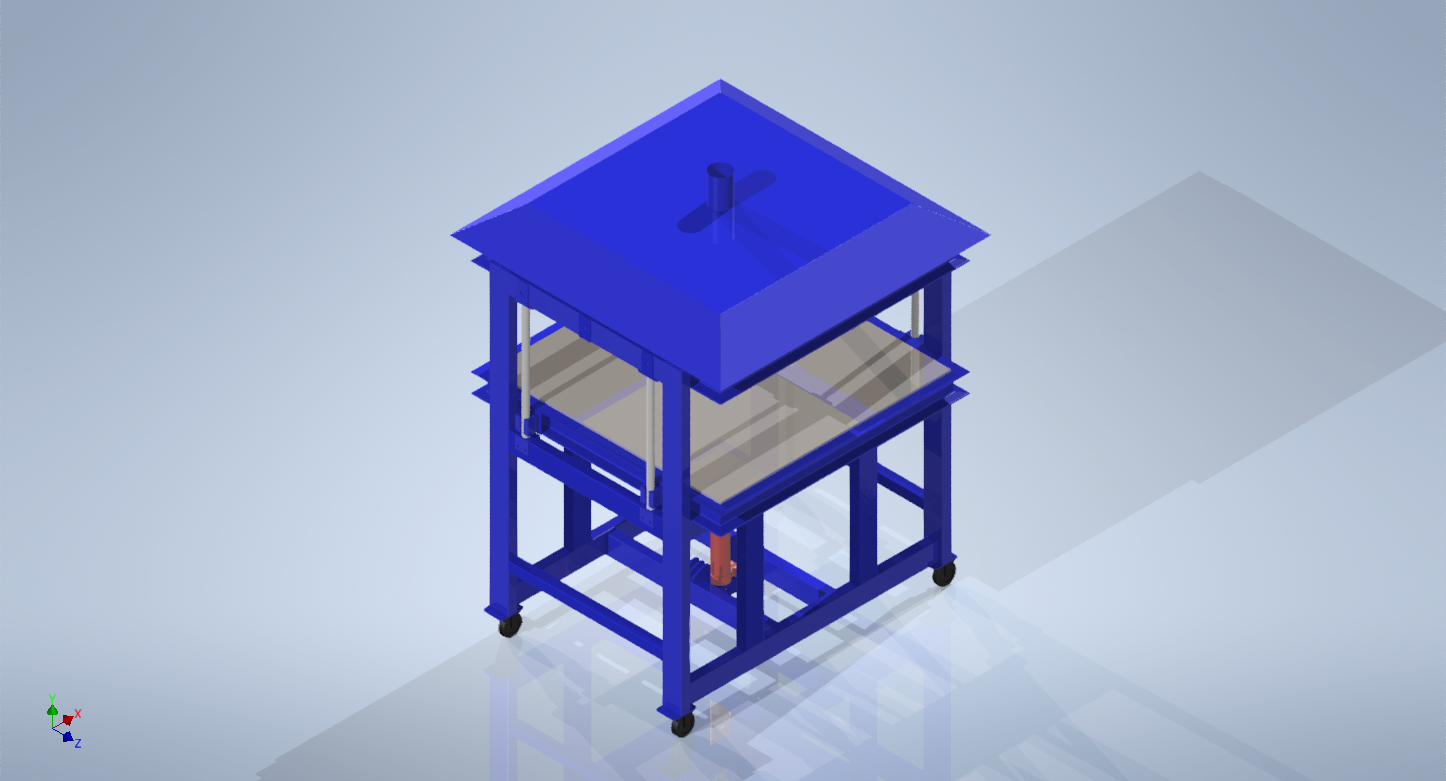

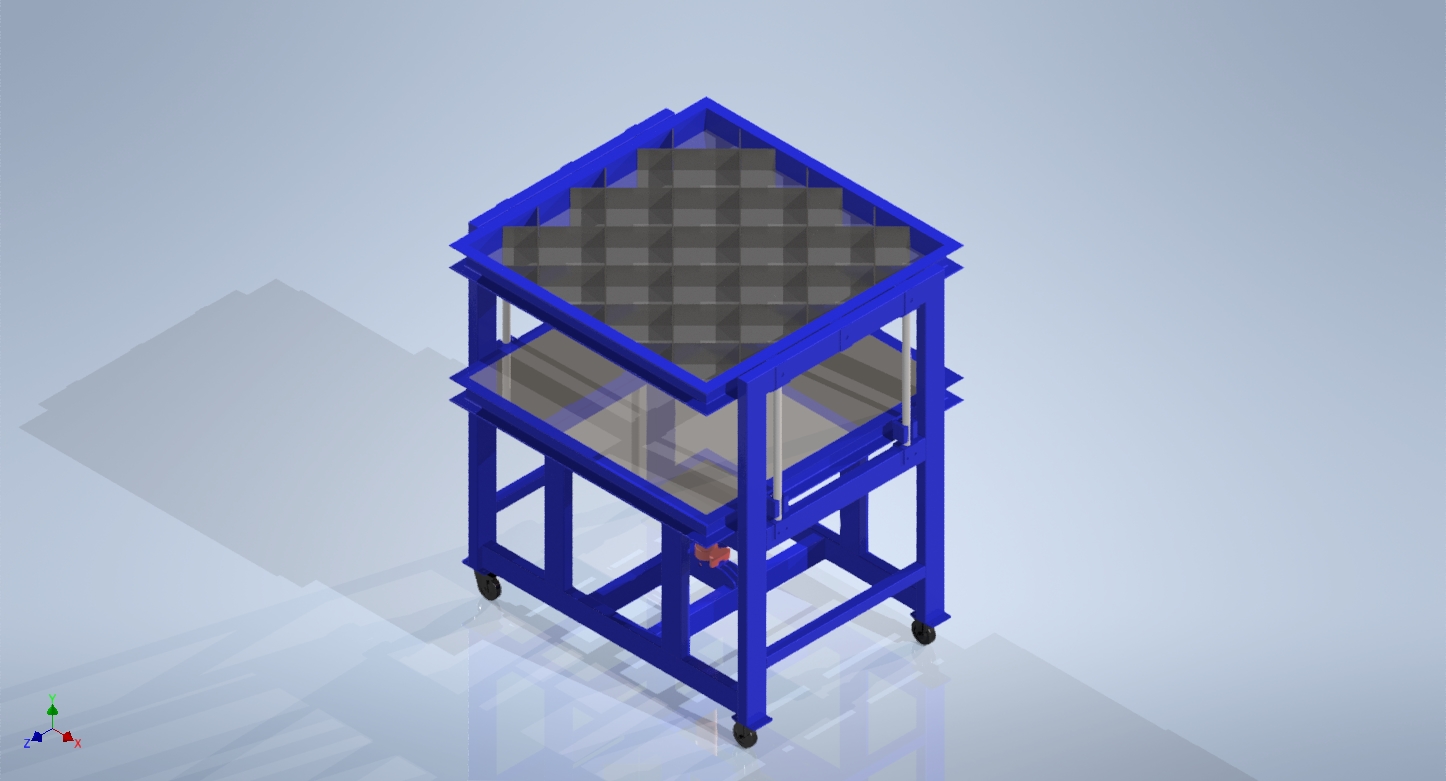

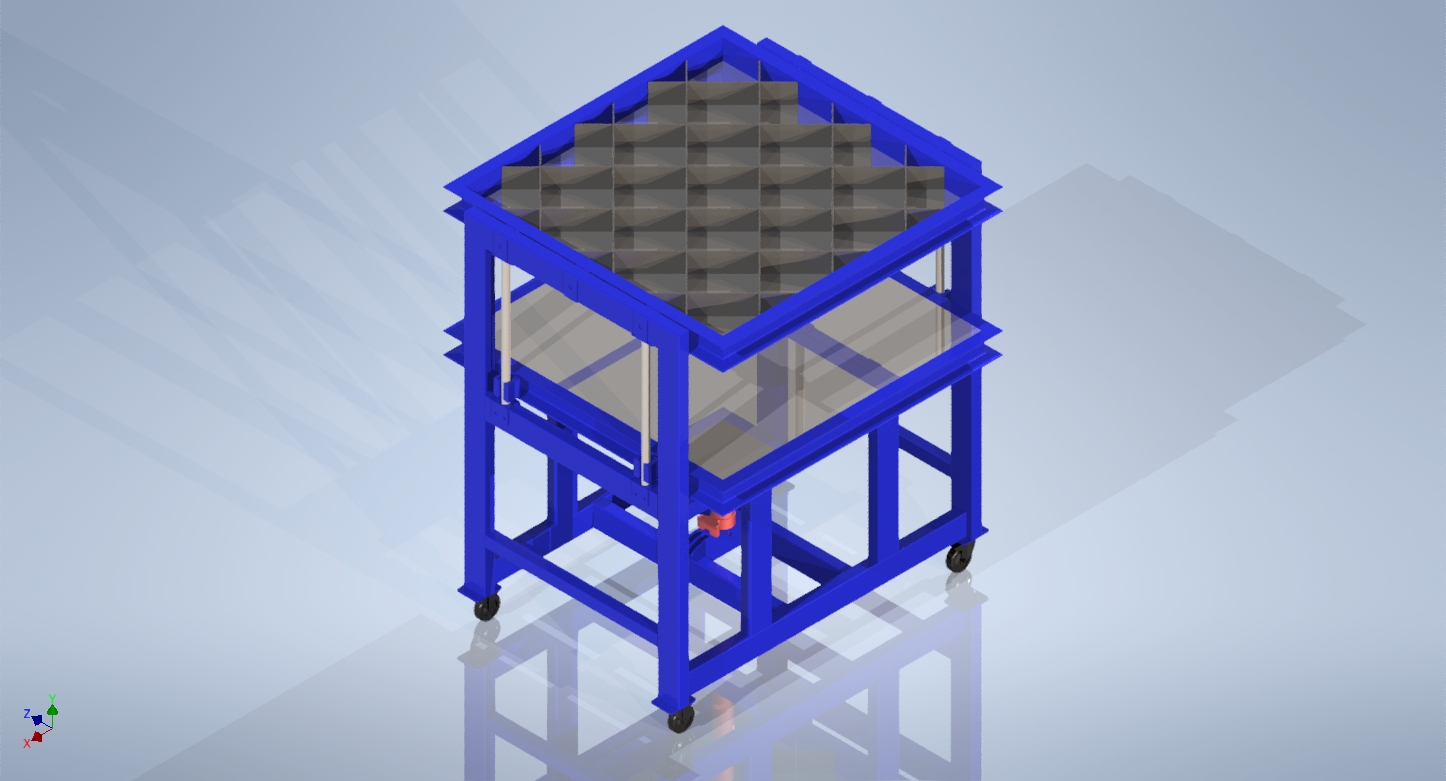

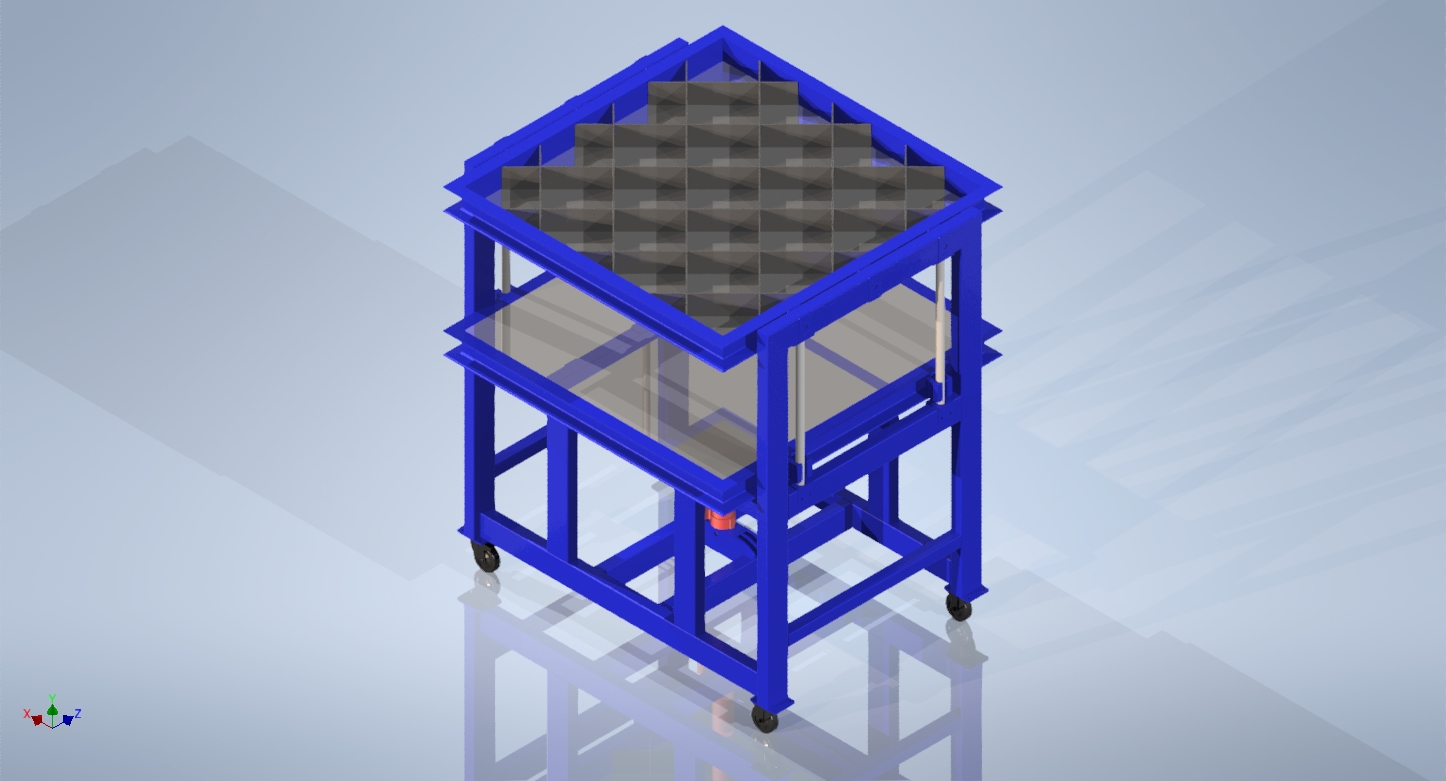

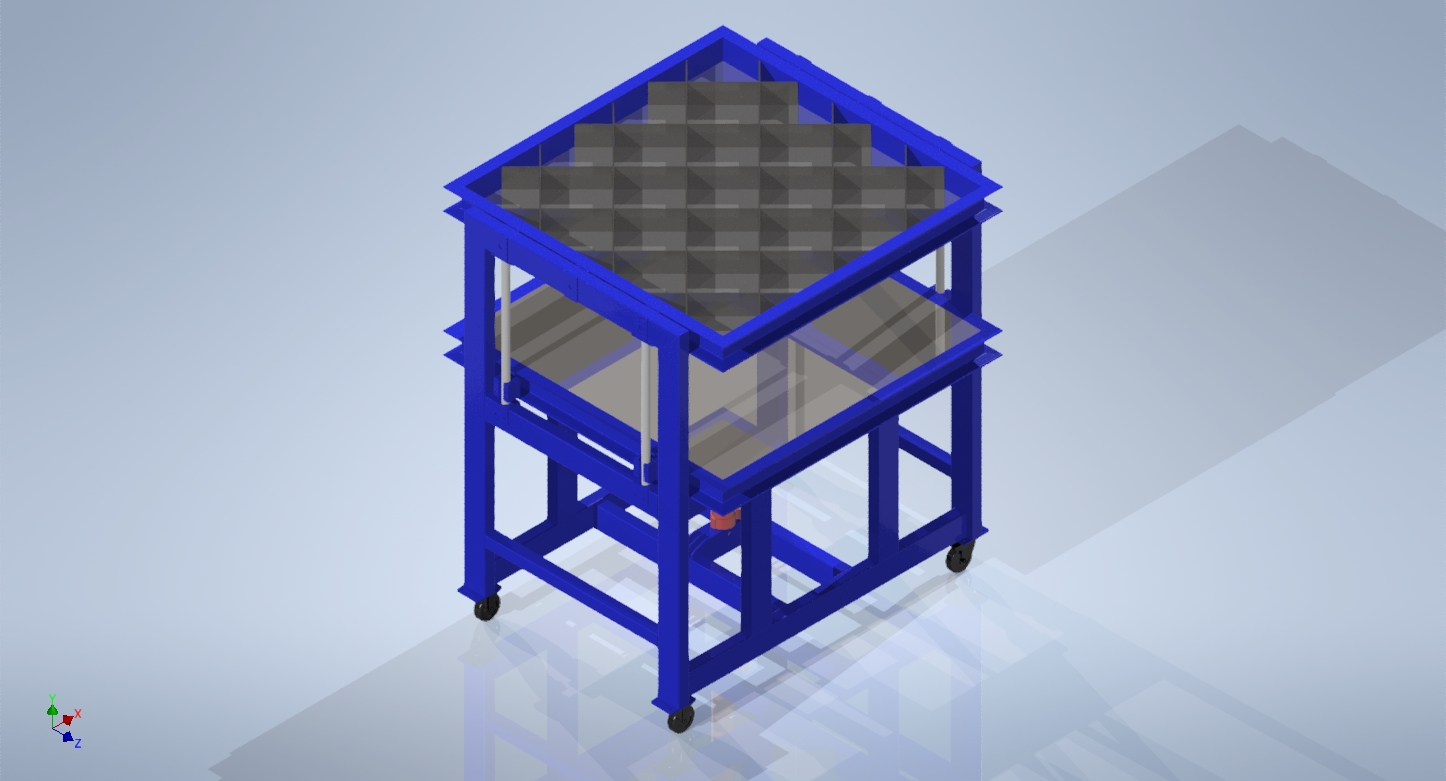

Transform your plastic waste into high-quality, usable sheets with our innovative Sheet Press Machine, designed for efficiency, durability, and versatility. Whether you’re a recycler, architect, or designer, this machine is a game-changer for creating sustainable materials.

Our Sheet Press Machine is the most popular in our product line. Why? It offers the highest return on investment by transforming plastic waste into durable sheets, which can be used like plywood for furniture, wall panels, and more. Here’s how it works:

With this dual system, you can create sheets with consistent quality, ready for use or further processing.

High Efficiency and Production Capacity

Superior Quality

Advanced Technology

We offer multiple configurations to suit your scale and budget:

| Models |

Manual

|

Semi-Automatic

|

|---|---|---|

| Electric Power | - | 17 kW, 380V |

| Weight Hot | ± 500kg | ± 700 kg |

| Weight Cold | ± 400kg | ± 500 kg |

| Electrical Power | 9,8 kW 380V | - |

| Power Pack Pump | - | 6 cc |

| Power Pack Tank Capacity | - | 8 Liter |

| Working Area | - | 120x120 cm |

| Pressure Hydraulic | - | 50 Bar |

| Work Area | 120x120cm | - |

| Power Pack Motor | - | 3 HP, 380V |

| Dimension | 147x147x200 cm | 147x147x230 mm |

| Frame Material | Hollow 100x50x1,7 mm | Hollow 100x50x2 mm |

Our customers have used the Sheet Press to create:

The machine processes a variety of plastics, including:

Proper sorting and cleaning ensure high-quality results, free from contaminants like sand or organic matter.

Space Requirements

Maintenance

Pair the Sheet Press with other recycling equipment for a complete plastic recycling line:

All of our machines come with 6 months of comprehensive warranty, and we offer maintenance services to ensure your investment lasts for years to come.

Whether you’re running a business or exploring creative uses for recycled materials, the Sheet Press Machine is your key to sustainable, high-quality production. Contact us today to learn more or place your order!

The development, production and delivery time heavily depends on the type and the size of the machine ordered and the availability of the parts we have to order from external suppliers. We'll provide you with an estimated delivery time window but things that are not in our control can cause delays at any time. However, we'll do our best to get your order out to you as fast as possible.

Our most popular machines, such as our plastic shredder, are available in different standard versions. Ordering a standard version usually cuts down the delivery time significantly. Please contact us for more detailed information.

Since all our machines are produced on request we usually don't stock spare parts. However, all parts that are made in house are normally available within a day or two depending on the availability of materials and the production time. The delivery time for spare parts from external suppliers can vary widely but, as usual, we'll go the extra mile to get your spare part to you as fast as possible.

Yes, Wedoo. Our field team is ready to help you with all your repair and maintenance requests. Since we don't have unlimited human resources and depending on your location and the production time for necessary spare parts it might take a day or two before our technician is able to help you.