Our Plastic Injection Machine is built for teams who want to go beyond shredding and washing—transforming recycled plastic into finished, functional products with reliable quality and repeatable results. Designed to work with properly sorted, washed, and dried plastics, it delivers smooth surfaces, stable shapes, and parts that are ready for use with minimal finishing.

Whether you are producing retail goods, functional components, replacement parts, or branded items, this machine helps you turn local waste into meaningful, high-value products.

Stable temperature and injection control help reduce common molding issues like warping, bubbles, short shots, or brittle sections—so you get more usable parts per cycle.

Instead of stopping at flakes or sheets, you can convert recycled material directly into sale-ready products that support business models, community programs, education projects, and manufacturing needs.

Because injection molding shapes the part inside the mold, components typically come out clean. Operators usually only need light trimming and a visual QC check before parts are ready to pack.

Logos, text, and design details can be engraved directly into your mold. That means branding, measurements, or functional labels appear directly on the molded part—no extra labeling or printing required.

Cycle repeats with stable timing, so production planning becomes easier and more predictable.

If your goal is to make repeatable parts in stable volumes, this machine is built for that.

Works best with common recycled polymers such as:

For best performance:

Clean feedstock = cleaner results.

Small habits make a big difference in product quality.

Shredder → Washer → Dryer → Plastic Injection → Trimming & Quality Check

Direct, compact, and efficient. No complex assembly line required.

Community Recycling Hubs Create local products for education, awareness, or retail programs.

SMEs & Workshops Produce functional components and replacement parts in-house.

Factories & Industrial Users Reduce dependence on external suppliers by molding recurring parts internally.

Education & Innovation Labs Demonstrate real plastic-to-product manufacturing in a practical, professional way.

Every operation is different. If you tell us:

We can help recommend the right configuration, mold strategy, and production approach so your plastic injection setup is efficient from day one.

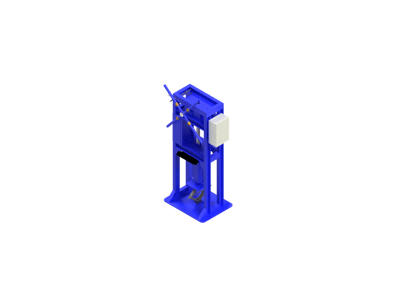

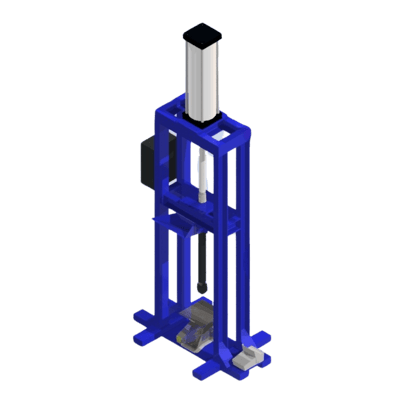

Key Specifications:

+ 2 more...

Key Specifications:

+ 3 more...

Key Specifications:

+ 3 more...

Compare specifications across all available models

| Specification | Manual | Standard | Pro |

|---|---|---|---|

| Barrel Capacity | 250ml | 150ml | 500ml |

| Dimensions | 620 x 485 x 1400 mm | 70x35x170 Cm | 92x60x230 Cm |

| Electrical Power | 1 kW/ 1.000 Watt | Electrical Power : 1 kW/ 1.000 Watt | 1,4 kW/ 1.400 Watt |

| Heater | 5 pcs heater 200w | 5 Pcs Heater 200w | 7 Pcs Nozzle Heater 200 Wat |

| Max Pressure | - | 10 Bar | 10 Bar |

| Weight | ± 100kg | ± 60 Kg | ± 100 Kg |

The development, production and delivery time heavily depends on the type and the size of the machine ordered and the availability of the parts we have to order from external suppliers. We'll provide you with an estimated delivery time window but things that are not in our control can cause delays at any time. However, we'll do our best to get your order out to you as fast as possible.

Our most popular machines, such as our plastic shredder, are available in different standard versions. Ordering a standard version usually cuts down the delivery time significantly. Please contact us for more detailed information.

Since all our machines are produced on request we usually don't stock spare parts. However, all parts that are made in house are normally available within a day or two depending on the availability of materials and the production time. The delivery time for spare parts from external suppliers can vary widely but, as usual, we'll go the extra mile to get your spare part to you as fast as possible.

Yes, Wedoo. Our field team is ready to help you with all your repair and maintenance requests. Since we don't have unlimited human resources and depending on your location and the production time for necessary spare parts it might take a day or two before our technician is able to help you.