Our Plastic Extruder is designed to take sorted, washed, and dried plastic and turn it into a steady, controllable melt stream—ready to become pellets, profiles, strips, or even free-form “toothpaste-like” shapes for creative making. It’s the machine you use when you want your recycled plastic to stop being waste, and start behaving like a reliable manufacturing material.

Simple workflow. Predictable results. Built for real daily use.

Consistent melt → better results downstream Stable temperature control helps produce smoother surfaces, fewer defects, and more predictable dimensions.

Flexible outcomes from one machine Store it as pellets. Turn it into strips or rods. Or push creative boundaries and lay “extruded beads” into forms, textures, and craft-level builds.

Fits naturally into a recycling line Works perfectly after Shredder → Washer → Dryer → Extruder → (Pelletizer / Sheet Press / Molding)

Operator-friendly controls Clear temperature zoning and screw-speed control help your team dial in the material and repeat the result again and again.

Pelletizing route Extrude strands → cool → cut → store pellets for future production or resale.

Profile / strip route Run through a die to create bands, rods, edging, handles, trim profiles, or preforms for later pressing or machining.

Creative / free-form route Apply a nozzle and lay down a “toothpaste-like” bead to draw, spiral, fill, emboss, or experiment with shapes and textures.

Small discipline = big improvement in quality.

Community & Micro-Manufacturing Turn collected plastic into usable forms that drive real circular value.

SMEs & Production Workshops Convert off-cuts into reusable pellets or profiles, stabilizing material availability and reducing virgin plastic use.

Studios, Labs & Education Perfect for demonstrating plastic transformation in a way that is visual, engaging, and hands-on.

Pick a machine capacity that matches your space and throughput goals. Choose dies / nozzles based on the shape you want to produce. Add cooling support or cutting where needed.

If you tell us your goal—pellets, strips, profiles, or creative forming—we can help recommend the right configuration so you start strong from day one.

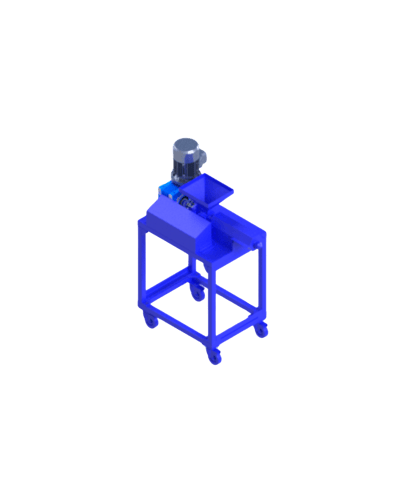

Key Specifications:

+ 4 more...

Key Specifications:

+ 4 more...

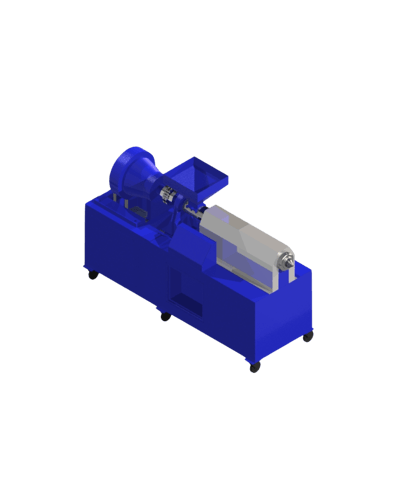

Key Specifications:

+ 4 more...

Key Specifications:

+ 4 more...

Compare specifications across all available models

| Specification | Mini | Standard | Pro | Pro Max |

|---|---|---|---|---|

| Dimensions | 100x60x120 cm | 160x80x140 cm | 220x80x140 cm | 260x80x160 cm |

| Electrical Power | 3 kW / 3.300 Watt | 7 kW / 7.000 Watt | 11,9 kW / 11.900 Watt | 15,5 kW / 15.500 Watt |

| Heater | 6 Pcs Ceramic Heater 250w | 6 Pcs ceramic heater 500W | 8 Pcs Ceramic Heater 800w | 8 Pcs Ceramic Heater 1000w |

| Max Capacity | 15 Kg/Hour | 40 Kg/h | 70 Kg/Hour | 100 Kg/h |

| Motor Power | 2 HP, 1,5kW, 380V | 5,5 HP, 4kW, 380V | 7.5 HP, 5,5 kW 380V | 10 HP, 7,5kW, 380V |

| Screw | Diameter 28mm, L : 600mm | Diameter 50mm, L : 800mm | Diameter 75mm, L :1250mm | Diameter 100mm, L : 1550mm |

| Weight | ± 50 Kg | ± 200 Kg | ±500 Kg | ±800 Kg |

The development, production and delivery time heavily depends on the type and the size of the machine ordered and the availability of the parts we have to order from external suppliers. We'll provide you with an estimated delivery time window but things that are not in our control can cause delays at any time. However, we'll do our best to get your order out to you as fast as possible.

Our most popular machines, such as our plastic shredder, are available in different standard versions. Ordering a standard version usually cuts down the delivery time significantly. Please contact us for more detailed information.

Since all our machines are produced on request we usually don't stock spare parts. However, all parts that are made in house are normally available within a day or two depending on the availability of materials and the production time. The delivery time for spare parts from external suppliers can vary widely but, as usual, we'll go the extra mile to get your spare part to you as fast as possible.

Yes, Wedoo. Our field team is ready to help you with all your repair and maintenance requests. Since we don't have unlimited human resources and depending on your location and the production time for necessary spare parts it might take a day or two before our technician is able to help you.