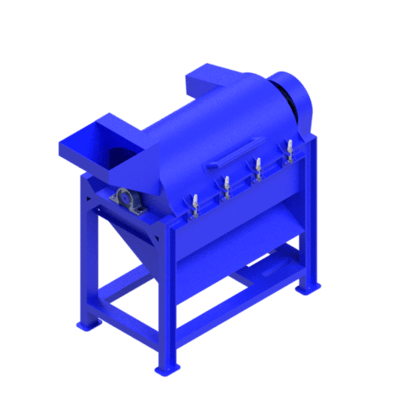

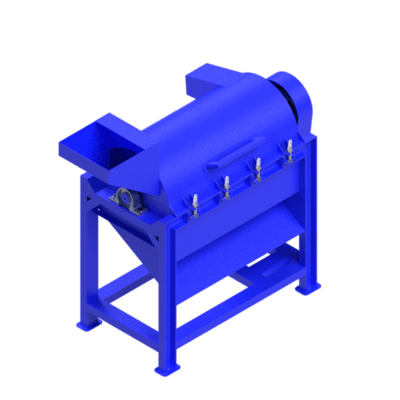

A focused, two-module coconut line: Cocopeat Unit to turn husk into peat-like growing media and coir fibers, and Coconut Crusher to chip husk/shell into uniform pieces for mulch, compost, or biochar feed.

Wedoo’s Coconut Machine is designed to make coconut processing faster, safer, and more efficient—especially for teams that are tired of heavy manual work and inconsistent output. This focused two-module setup allows you to handle husk and shell materials with ease while turning them into valuable products that can be sold, reused, or processed further.

The system is built around two core modules that can work individually or as part of a complete line:

Material is loaded through a guarded infeed, processed efficiently, and discharged as clean, ready-to-use output.

From the Cocopeat Unit

From the Coconut Crusher

This configuration focuses specifically on cocopeat production and husk/shell crushing. It does not include edible processing or oil extraction.

The machine is designed to be easy for your team to learn and operate. Clear sightlines reduce guesswork, controls are intuitive, and service points are accessible, making inspections and maintenance straightforward.

If you tell us your industry, material type, daily volume, and final output goals, we’ll help recommend the right configuration.

Key Specifications:

+ 3 more...

Key Specifications:

+ 3 more...

No Image

Key Specifications:

+ 3 more...

No Image

Key Specifications:

+ 4 more...

Compare specifications across all available models

| Specification | Cocopeat Mini | Cocopeat Standard | Coconut Crusher Mini | Coconut Crusher Standard |

|---|---|---|---|---|

| Blades | 24pcs 10mm | 27 Pcs 10mm | 6pcs Sharp Blade and 8pcs Dull Blade | 12x Blade HRC 57 |

| Dimension | 145x70x135cm | 145x70x135cm | 120x80x140cm | 170x100x150 Cm |

| Electrical Power | 3 kW / 3.000 Watt | 5,5HP/5.500 Wat | 4 kW / 4.000 Watt | 5,5HP/5.500 Watt |

| Max Capacity | 90 Kg/Hour | 300 Kg/Hour | 40kg/Hour | 150 Kg/Hour |

| Motor Power | 4HP, 380V | 7,5 HP, 380V | 5.5 HP, 380V | 7,5 HP, 380V |

| Shaft | - | - | - | S45C D 60mm |

| Weight | ± 100 Kg | ± 150 Kg | ± 250 kg | ± 450 Kg |

The development, production and delivery time heavily depends on the type and the size of the machine ordered and the availability of the parts we have to order from external suppliers. We'll provide you with an estimated delivery time window but things that are not in our control can cause delays at any time. However, we'll do our best to get your order out to you as fast as possible.

Our most popular machines, such as our plastic shredder, are available in different standard versions. Ordering a standard version usually cuts down the delivery time significantly. Please contact us for more detailed information.

Since all our machines are produced on request we usually don't stock spare parts. However, all parts that are made in house are normally available within a day or two depending on the availability of materials and the production time. The delivery time for spare parts from external suppliers can vary widely but, as usual, we'll go the extra mile to get your spare part to you as fast as possible.

Yes, Wedoo. Our field team is ready to help you with all your repair and maintenance requests. Since we don't have unlimited human resources and depending on your location and the production time for necessary spare parts it might take a day or two before our technician is able to help you.