For many teams, this is the moment that matters most. You’ve collected material, processed it, pressed it into sheets… and now you need precise, clean, repeatable parts. The Wedoo CNC Router is built to do exactly that—turning recycled plastic boards, wood panels, and aluminum sheets into real, high-quality products with accuracy you can trust.

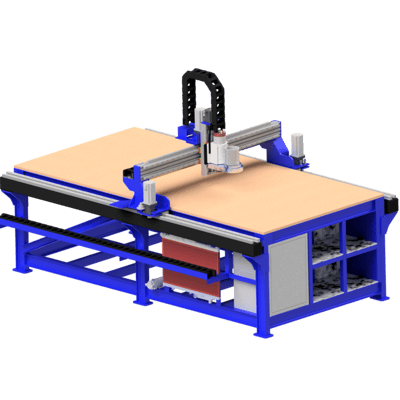

This router is engineered for production environments, not just labs or hobby spaces. With a 120 × 120 cm work area, a strong 50 × 50 hollow frame, aluminum reinforcement, a 1.5 kW water-cooled spindle, and stable NEMA motors, it delivers the rigidity and control required for consistent cutting performance. Powered by the DSP A11 controller, the machine runs fully offline via USB, which keeps the workflow simple, reliable, and workshop-friendly.

If your goal is not only to experiment—but to actually manufacture—this machine is designed to support you.

The CNC process shouldn’t slow you down or require a specialist just to get through a job. Our workflow is practical and straightforward:

Design your part → prepare your toolpath → copy to USB → load on DSP → secure your sheet → run.

That’s it.

No constant PC connection. No internet dependency. No unnecessary complexity on the production floor. Operators can learn it, teams can standardize it, and businesses can rely on it.

Software Recommendation For most users, we recommend using Aspire for preparing designs and toolpaths. It’s intuitive, reliable, and works smoothly with our CNC workflow—especially when handling recycled plastic sheets and complex cutting projects.

Although it shines with recycled plastic boards, this CNC isn’t limited to one material. With the right tooling and feeds, it performs confidently with:

That flexibility means you can use one machine for multiple product lines or development needs—whether you’re prototyping, customizing, or running production batches.

This is the kind of machine that quietly becomes essential. The one everyone depends on because it “just works.”

Shredder → Washer → Dryer → Sheet Press → 👉 Wedoo CNC Router → Finishing → Assembly

This is where your boards stop being “material” and start becoming products.

Small habits create big differences in output quality.

Choose this CNC if you are:

If you tell us what materials you use, what you want to produce, and how often you plan to run the machine, we’ll help recommend the most suitable setup and workflow for your needs.

No Image

Key Specifications:

+ 4 more...

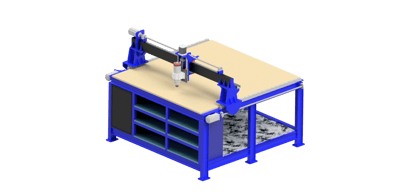

Standard variant of CNC Router

Key Specifications:

+ 4 more...

Key Specifications:

+ 4 more...

Compare specifications across all available models

| Specification | CNC Mini | CNC Standard | CNC Pro |

|---|---|---|---|

| Control | DSP A11 | DSP A11 | DSP A11 |

| Dimension | 150 x 120 x 80 Cm | 210x180x160 Cm | 210x300x160 cm |

| Electrical Voltage | 3kW, 220V | 5 kW, 220v | 5kW, 380v |

| Motor | Nema 24 | Nema 34 | Nema 34 |

| Spindle | 1,5 kw | 1.5 kw, 380v Water Cooling | 3kw, 380v water cooling |

| Weight | ± 250 kg | ± 500 Kg | ± 700 kg |

| Work Area | 60 x 60 cm | 120x120x15 Cm | 120 x 240 cm |

The development, production and delivery time heavily depends on the type and the size of the machine ordered and the availability of the parts we have to order from external suppliers. We'll provide you with an estimated delivery time window but things that are not in our control can cause delays at any time. However, we'll do our best to get your order out to you as fast as possible.

Our most popular machines, such as our plastic shredder, are available in different standard versions. Ordering a standard version usually cuts down the delivery time significantly. Please contact us for more detailed information.

Since all our machines are produced on request we usually don't stock spare parts. However, all parts that are made in house are normally available within a day or two depending on the availability of materials and the production time. The delivery time for spare parts from external suppliers can vary widely but, as usual, we'll go the extra mile to get your spare part to you as fast as possible.

Yes, Wedoo. Our field team is ready to help you with all your repair and maintenance requests. Since we don't have unlimited human resources and depending on your location and the production time for necessary spare parts it might take a day or two before our technician is able to help you.