Most F&B businesses treat plastic waste as a cost. Kopi Nako treats it as a resource. Their approach offers a model that any café or restaurant chain can adopt if they want to improve efficiency, reduce environmental impact, and strengthen brand identity. Wedoo’s recycling machines sit at the center of this shift.

How one of Indonesia’s fastest-growing café chains builds circularity into its daily operations

In today’s competitive food and beverage landscape, sustainability is not just a marketing buzzword — it’s a strategic requirement. F&B brands that fail to address waste, especially plastic, face rising costs, regulatory pressure, and shifting customer expectations. Kopi Nako, one of Indonesia’s fastest-growing café chains, recognized this early. Instead of treating plastic waste as an unavoidable byproduct, they turned it into a resource. With the support of Wedoo’s recycled-plastic machinery, Kopi Nako built a circular system that converts their used cups into durable furniture, signage, and architectural elements across their outlets. Kompas

The Challenge: A Rapidly Growing Business and A Growing Plastic Footprint

As Kopi Nako expanded across Indonesia, plastic to-go cups accumulated at a scale that felt increasingly unsustainable. Traditional waste management options — outsourcing to recyclers or paying for disposal — were costly, inconsistent, and environmentally insufficient.

Three realities pushed Kopi Nako to rethink their approach:

- Their logistics trucks returned to Bogor empty after delivering supplies.

- Customers generated thousands of single-use polypropylene (PP) cups every week.

- Without intervention, these cups would likely end up in landfills or leak into the environment.

Kopi Nako’s leadership understood that managing waste wasn’t enough. They needed a closed-loop system that brought the plastic back into their control and turned it into something useful.

The Solution: Circular Infrastructure Powered by Wedoo Technology

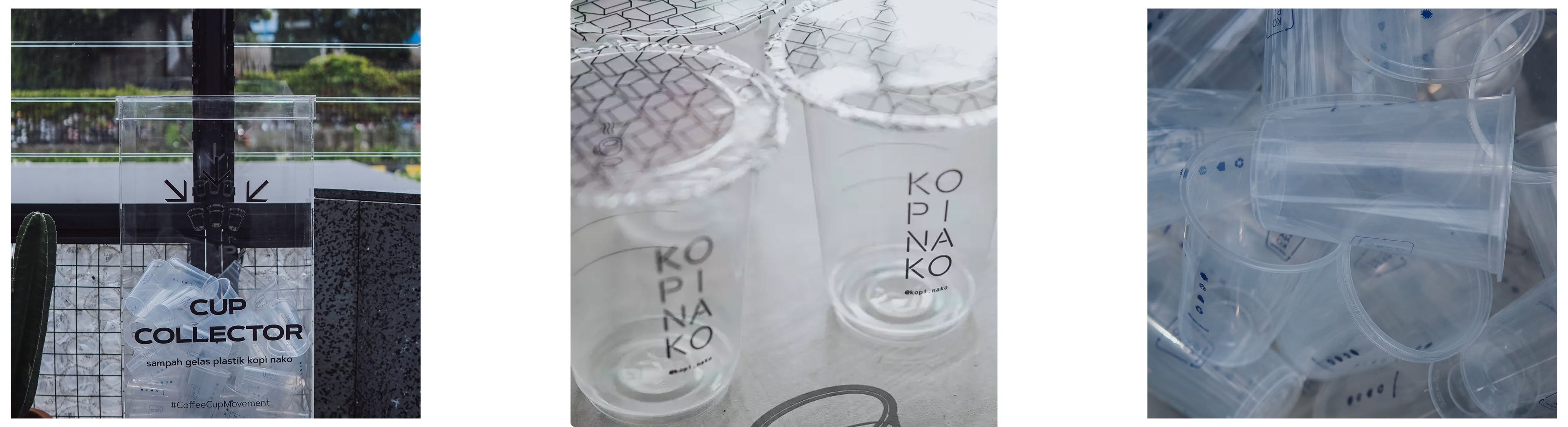

1. Engaging Customers Through Rinse & Collect Stations

Kopi Nako installed “Rinse & Collect” stations in every branch, allowing customers to quickly rinse their cups in roughly seven seconds before disposing of them in dedicated bins — an initiative branded as the Seven-Sec Action. This simple step prevents odor and contamination, making the collected PP cups easier to transport and recycle. After collection, the cups are loaded onto the returning logistics trucks, maximizing existing routes without additional fuel or operational cost. As Kompas reported, “the box truck leaves carrying coffee, and returns carrying plastic waste.”

2. Micro-Factory Processing at the Daur Baur Facility

At Kopi Nako’s mini recycling hub — the Daur Baur Micro Factory in Bogor — the incoming cups move through a structured process: sorting, de-labeling, shredding, washing, and molding. Here, Wedoo’s Sheet Press Set plays a critical role. The machine applies controlled heat and pressure to transform plastic flakes into high-quality recycled sheets, usually sized 1 × 1 meters. Depending on thickness, each sheet takes about 30–60 minutes to produce.

This system gives Kopi Nako what traditional recyclers rarely offer: transparency, consistency, and direct control over the material output.

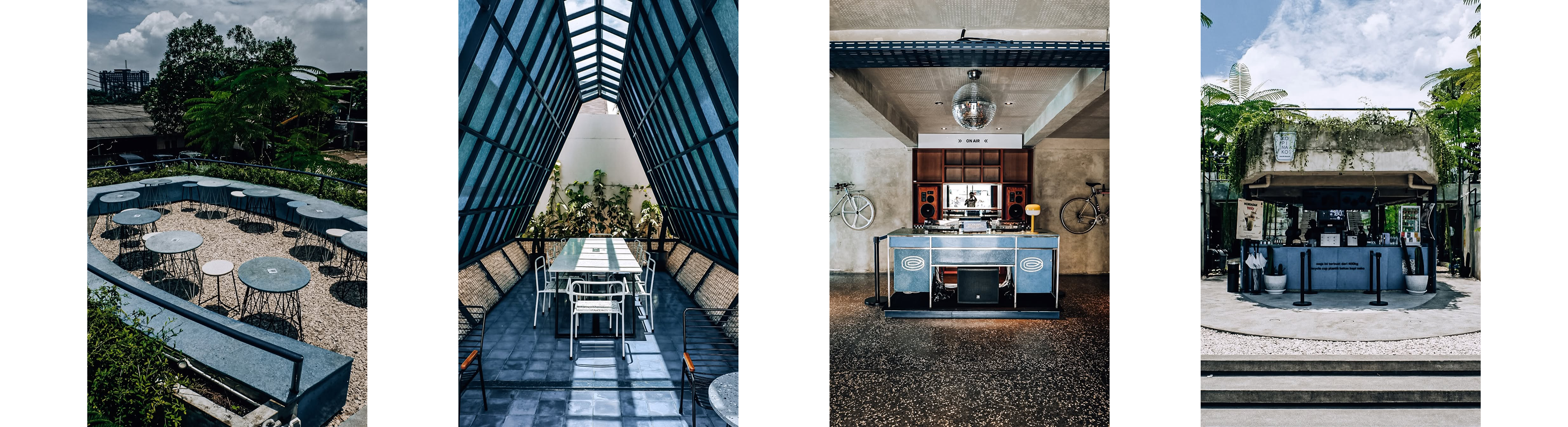

3. Transforming Plastic Sheets Into Café Assets

These recycled sheets become functional, long-lasting materials used across Kopi Nako’s outlets:

- Tables, bar tops, stools, and benches for 60+ outlets

- Interior wall panels, signage, and other architectural elements

- Custom design collaborations, including a notable ATM-wall installation for BCA using recycled-plastic panels

By internalizing this process, Kopi Nako reduces waste, lowers material-procurement costs, and maintains consistent design aesthetics across their growing network.

The Impact: Environmental, Operational, and Brand-Level Value

Kopi Nako’s circular model generates measurable outcomes:

- Large-scale waste diversion. One furniture item alone can use up to 0.5 tons of recycled cups, resulting in tons of plastic being repurposed each year.

- Operational efficiency. Reverse logistics utilizes empty truck space, eliminating the need for separate waste-collection services.

- Brand differentiation. Their Daur Baur outlets make sustainability visible — customers see recycled-plastic walls, tables, and installations on every visit.

- Scalability. As Kopi Nako opens new branches, their micro-factory and Wedoo’s modular machines scale alongside them.

Beyond recycling, Kopi Nako incorporates sustainability into brand storytelling. Some outlets feature plastic-cup “wiremesh walls” made from hundreds of processed cups, while menu innovations like the Oat Latte Macadamia connect sustainable values with product experience. Kompas

Why This Matters for F&B Businesses Considering Circularity

For any café, restaurant, or food service brand that manages large volumes of plastic waste, Kopi Nako’s model shows that circularity is realistic and scalable. Turning used cups or containers into new assets gives businesses greater control over their waste stream, reduces long-term procurement costs, and strengthens customer trust through visible sustainability practices. It also opens new storytelling opportunities that set a brand apart in a crowded market.

Wedoo’s machinery supports this model by giving F&B operators the ability to process their own waste into high-value materials. The systems are engineered specifically for recycled-plastic production, designed and manufactured in Bali for fast support, and modular enough to fit both small and large operations. These machines already power recycling workflows in cafés, hotels, community hubs, and social enterprises across Indonesia.

For leaders ready to explore circularity, the path forward is straightforward. Start by examining your monthly waste output and identifying which materials can be recovered. Define how these materials could re-enter your operations as furniture, interior elements, or branded assets. When you're ready, Wedoo can help you evaluate your waste stream, design a micro-factory workflow, and build a solution tailored to your business model.

Conclusion

Kopi Nako’s work with Wedoo shows what’s possible when a modern F&B brand doesn’t just minimize its environmental footprint — but transforms it into value. By converting their own plastic waste into usable materials, they’ve built a resilient, scalable, and future-oriented circular ecosystem.

This is more than a case study. It’s a blueprint for the future of the F&B industry.